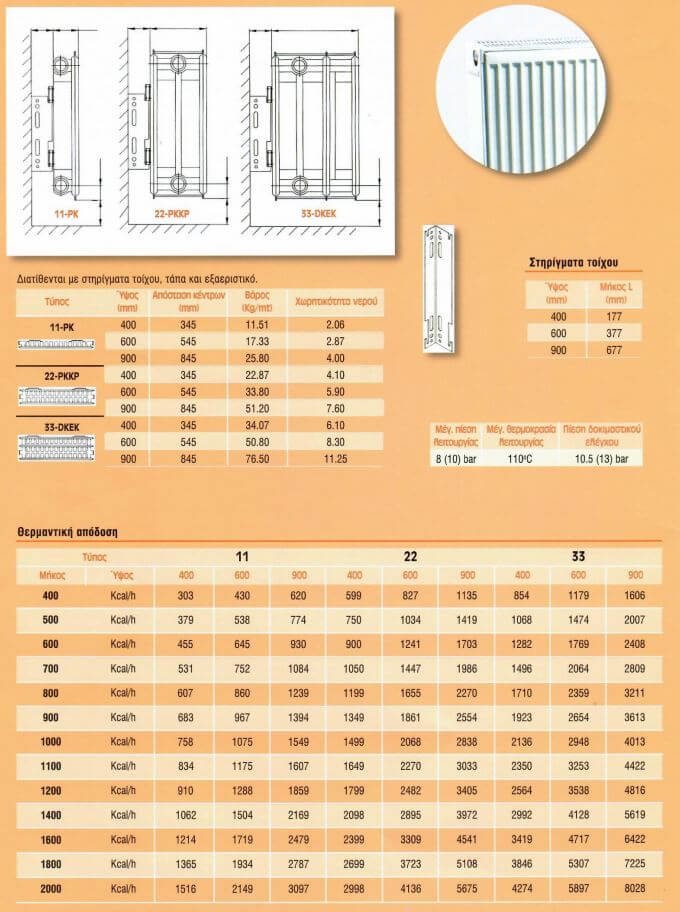

Panel type radiator 22×600

33.95€ – 162.10€

SPLENDID panel radiators are designed for high thermal performance and pressure resistance through computer virtual analysis of design programs in collaboration with the German scientific institute for heating HLK in Stuttgart.

SPLENDID heating panels are produced from cold rolled steel with modern technology and as a result have perfect surfaces. Their welding is done by a fully automated process with computer controlled systems All panels are controlled 100% with a pressure of 10.5bar (13bar)

SPLENDID panel surfaces are chemically cleaned and treated with phosphating by spraying. They are then dipped in primer and dried in ovens. The color coating is done with electrostatic epoxy powder paint (White RAL 9010) and they are dried in ovens (200C) according to DIN 55900 specifications. The panels are packed in nylon with bubbles and cardboard corners to protect against knocks. Additionally, the panels are covered with heat-shrinkable nylon to protect against dust and moisture.

SPLENDID heating panels are available in three different models and three heights (400-600-900mm). Their length varies from 400 to 2000mm. Thanks to their small capacity in water with an optimal pitch of 33mm, they offer high performance and simultaneously save operating costs. Their patented suspension system, which is done from the wall or alternatively with the use of additional parts from the floor.

SPLENDID heating panels are produced with years of experience through processes that have been tested and approved by international organizations for their quality certification according to ISO 9001, TSE, DIN and EN442 specifications.

| Manufacturer | |

|---|---|

| Group SKU |

Piping - Insulation

Piping - Insulation  Piping Fittings

Piping Fittings  Valves - Cannulas

Valves - Cannulas  Drains

Drains  Water tanks - Accessories

Water tanks - Accessories  Support - Tables

Support - Tables  Spiral

Spiral  24x19 components

24x19 components  Welding - Sealing

Welding - Sealing  Water filter

Water filter  Various Plumbing Items

Various Plumbing Items

Water tanks

Water tanks  Bathroom Sinks

Bathroom Sinks  Tiles

Tiles  Bathroom accessories

Bathroom accessories  Mirrors

Mirrors  Ventilation Accessories

Ventilation Accessories  Bathroom lighting

Bathroom lighting  Basin Covers

Basin Covers  Basins

Basins  Shower Columns

Shower Columns  Bathroom furnishings

Bathroom furnishings  Bathroom cabins

Bathroom cabins  Showers

Showers  Sinks

Sinks

Kitchen faucets

Kitchen faucets  Bathroom batteries

Bathroom batteries  Sink batteries

Sink batteries  Built-in batteries

Built-in batteries  Bidet faucets

Bidet faucets  Battery Spare Parts

Battery Spare Parts

Fireplaces

Fireplaces  Boilers - Burners

Boilers - Burners  Heat pumps

Heat pumps  Circulators

Circulators  Heating Devices

Heating Devices  Radiator bodies

Radiator bodies  LPG accessories

LPG accessories  accessory

accessory  Spare parts

Spare parts  Heating accessories

Heating accessories  Chimneys

Chimneys  Plastic tanks

Plastic tanks  Air conditioners

Air conditioners  Fans

Fans  Dehumidifiers

Dehumidifiers

Sockets - Switches

Sockets - Switches  Paintings

Paintings  Electrical Boxes - Buat

Electrical Boxes - Buat  Raga materials

Raga materials  Lightning Protection & Grounding

Lightning Protection & Grounding  Fishing Reels - Extensions

Fishing Reels - Extensions  Plug - Socket - Power socket - Adapters

Plug - Socket - Power socket - Adapters  Intercoms - Intercoms

Intercoms - Intercoms  Dui

Dui  Channels - Accessories

Channels - Accessories  UPS - Voltage Stabilizers

UPS - Voltage Stabilizers  Absorbers

Absorbers  Television Accessories - Antennas

Television Accessories - Antennas  Connection & Support Materials

Connection & Support Materials  Various Industrial Facilities

Various Industrial Facilities  Installation Pipes

Installation Pipes  Various materials

Various materials  Alarms & Accessories

Alarms & Accessories  Cables

Cables  Consumables

Consumables

LED lamps

LED lamps  Headlights

Headlights  Indoor Lighting

Indoor Lighting  Outdoor Lighting

Outdoor Lighting  LED Power Supplies - Controllers & Dimmers

LED Power Supplies - Controllers & Dimmers  LED strips

LED strips  Decorative

Decorative  Various Lamps

Various Lamps  Fluorine lamps

Fluorine lamps  Professional Lighting

Professional Lighting  Halogen lamps

Halogen lamps  Linear Luminaires

Linear Luminaires  Rails - LED Rail Lights

Rails - LED Rail Lights  accessory

accessory  Pear

Pear  G9 & G4

G9 & G4  Tube

Tube  Special Applications

Special Applications  Candle

Candle  Spot - GU10 - Studs

Spot - GU10 - Studs  Globe

Globe  Mirror

Mirror

Boiler

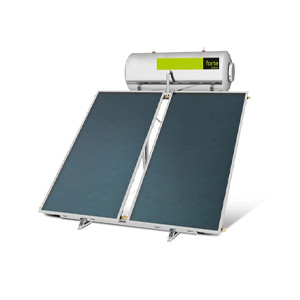

Boiler  Solar

Solar  Inertia Containers

Inertia Containers  Solar cover

Solar cover  Water heaters

Water heaters  Wood-Electric Water Heaters

Wood-Electric Water Heaters

Hand tools

Hand tools  Blades & Blades

Blades & Blades  Cleaners - Technical Sprays

Cleaners - Technical Sprays  Toolboxes

Toolboxes  Protective Items

Protective Items  Water pumps

Water pumps  Cutting Discs

Cutting Discs  Drills - Bits

Drills - Bits  Building materials

Building materials  Adhesive Films

Adhesive Films  Cleaning Brushes

Cleaning Brushes  Connections-Watering Fittings

Connections-Watering Fittings  Water Guns/Throwers

Water Guns/Throwers  Compressors - Vacuums

Compressors - Vacuums  Various materials

Various materials

Piping - Insulation

Piping - Insulation Piping Fittings

Piping Fittings Valves – Cannulas

Valves – Cannulas Drains

Drains Tanks - Accessories

Tanks - Accessories Support – Tables

Support – Tables Spiral

Spiral 24×19 fittings

24×19 fittings Welding - Sealing

Welding - Sealing Water filter

Water filter Various Plumbing Items

Various Plumbing Items Water tanks

Water tanks Bathroom Sinks

Bathroom Sinks Tiles

Tiles Bathroom accessories

Bathroom accessories Mirrors

Mirrors Bathroom lighting

Bathroom lighting Ventilation Accessories

Ventilation Accessories Basin Covers

Basin Covers Basins

Basins Shower Columns

Shower Columns Bathroom cabins

Bathroom cabins Showers

Showers Sinks

Sinks Bathroom batteries

Bathroom batteries Sink batteries

Sink batteries Built-in batteries

Built-in batteries Bidet faucets

Bidet faucets Battery Spare Parts

Battery Spare Parts Fireplaces

Fireplaces Boilers - Burners

Boilers - Burners Heat pumps

Heat pumps Circulators

Circulators Heating Devices

Heating Devices Radiator bodies

Radiator bodies LPG accessories

LPG accessories accessory

accessory Spare parts

Spare parts Heating accessories

Heating accessories Chimneys

Chimneys Plastic tanks

Plastic tanks Air conditioners

Air conditioners Fans

Fans Dehumidifiers

Dehumidifiers Sockets - Switches

Sockets - Switches Paintings

Paintings Electrical Boxes - Buat

Electrical Boxes - Buat Raga materials

Raga materials Lightning Protection & Grounding

Lightning Protection & Grounding Fishing Reels – Extensions

Fishing Reels – Extensions Plug - Socket - Power socket - Adapters

Plug - Socket - Power socket - Adapters Dui

Dui Channels – Accessories

Channels – Accessories UPS – Voltage Stabilizers

UPS – Voltage Stabilizers Television Accessories – Antennas

Television Accessories – Antennas Connection & Support Materials

Connection & Support Materials Various Industrial Facilities

Various Industrial Facilities Installation Pipes

Installation Pipes Various materials

Various materials Alarms & Accessories

Alarms & Accessories Cables

Cables Consumables

Consumables Water heaters

Water heaters Solar

Solar Boiler

Boiler Wood-Electric Water Heaters

Wood-Electric Water Heaters LED lamps

LED lamps Headlights

Headlights Indoor Lighting

Indoor Lighting Outdoor Lighting

Outdoor Lighting LED Power Supplies – Controllers & Dimmers

LED Power Supplies – Controllers & Dimmers LED strips

LED strips Decorative

Decorative Various Lamps

Various Lamps Fluorine lamps

Fluorine lamps Professional Lighting

Professional Lighting Halogen lamps

Halogen lamps Linear Luminaires

Linear Luminaires Tracks – LED Track Lights

Tracks – LED Track Lights accessory

accessory Hand tools

Hand tools Blades & Blades

Blades & Blades Cleaners - Technical Sprays

Cleaners - Technical Sprays Toolboxes

Toolboxes Protective Items

Protective Items Water pumps

Water pumps Cutting Discs

Cutting Discs Drills – Bits

Drills – Bits Building materials

Building materials Adhesive Films

Adhesive Films Cleaning Brushes

Cleaning Brushes Connections-Watering Fittings

Connections-Watering Fittings Compressors – Vacuums

Compressors – Vacuums Water Guns/Throwers

Water Guns/Throwers Various materials

Various materials